The H48 truss CNC lathe is a patented product of our company, with patent number ZL20182077626.7.

A type of integrated asynchronous bed head, ZL201821895511.4 CNC lathe with a direct drive spindle.

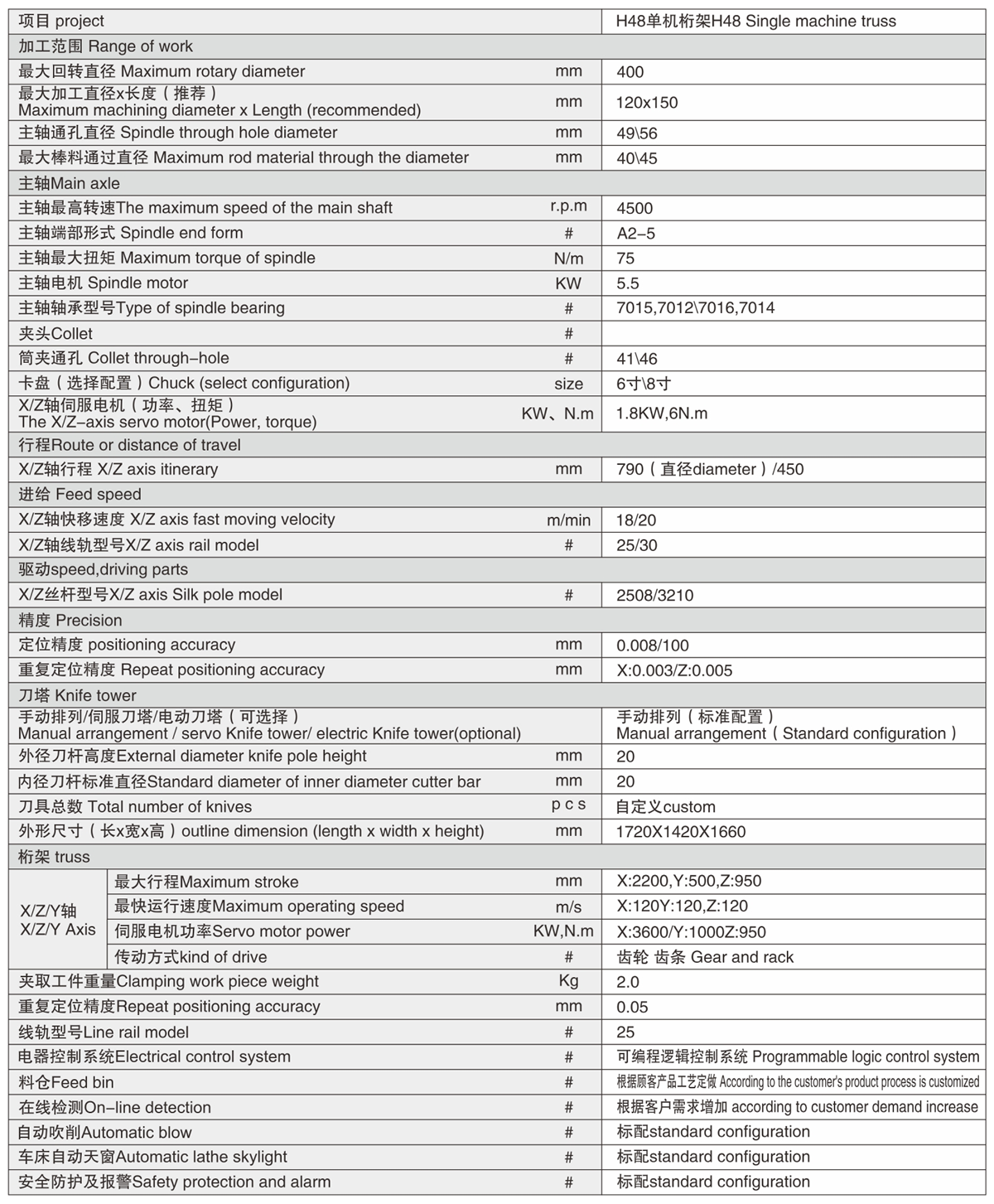

This CNC lathe is equipped with a semi closed-loop control CNC lathe system as standard.

The host adopts a 30 ° inclined guide rail layout, with the X-axis and Z-axis in the same plane.

The spindle (C-axis) is an AC asynchronous servo spindle directly driven by a driveless mechanism, which achieves position control and speed control. The spindle can rotate, feed, index, and stop accurately, and can be extended to two axes in the later stage on the drag plate.

Spindle clamping is achieved by using a hydraulic rotary cylinder to drive a three jaw chuck or an elastic chuck to clamp the workpiece.

X. Z is driven by ball screws, rolling linear guides, and the drag plate can automatically eliminate the reverse clearance of the drag plate by gravity; The guide rail protection adopts full protection and adopts absolute value AC servo motor.

Machine tools have good dynamic characteristics, high accuracy, and strong rigidity.

The machine tool and truss manipulator are integrated to achieve automatic loading and unloading of workpieces. The truss manipulator adopts a dot matrix structure, and there are multiple ways to choose from the material bin.

Contacts Us

Chat with us

Do you have any questions or suggestions? Please contact us. Our working hours are from 9am to 6pm