The V 230 CNC machine tool is a vertical lathe.

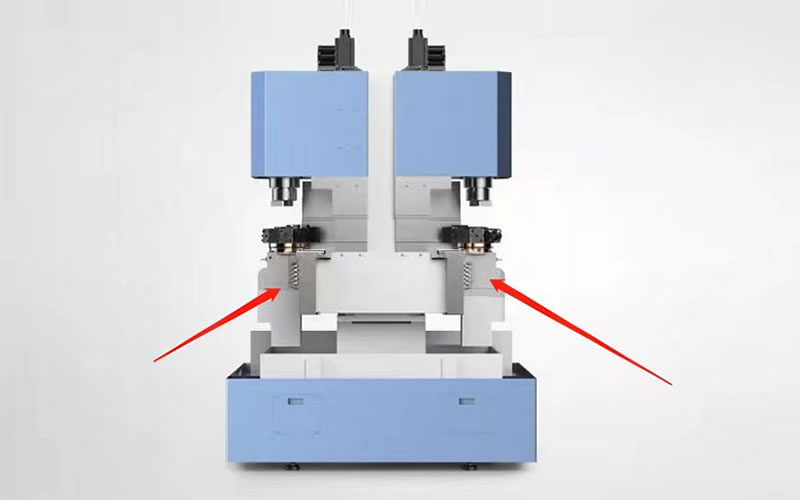

It adopts an inverted spindle and a dual station layout.

Its characteristic is that the feed axes X1, Z1, X2, and Z2 are fixed on the left and right sides of the bed, with X and Z perpendicular to each other, which is different from the overlapping structure of traditional workbenches.

The advantage is that the height of the worktable is reduced, greatly enhancing the rigidity of the worktable, and the cutting chip rigidity of the machine tool is strong.

The spindle C1 and C2 are inverted and fixed on the Z1 and Z2 axis workbenches, which is beneficial for chip collection.

Z1 and Z2 axes are aligned with the horizontal plane, and this type of CNC lathe adopts our company's patented technology, patent number: ZL201820777626.7.

Integrated asynchronous front end, ZL201821895511.4 CNC lathe with direct drive spindle, ZL 202223359025X (inverted CNC lathe structure), ZL2018218954592 (machine tool with gas-liquid balance system).

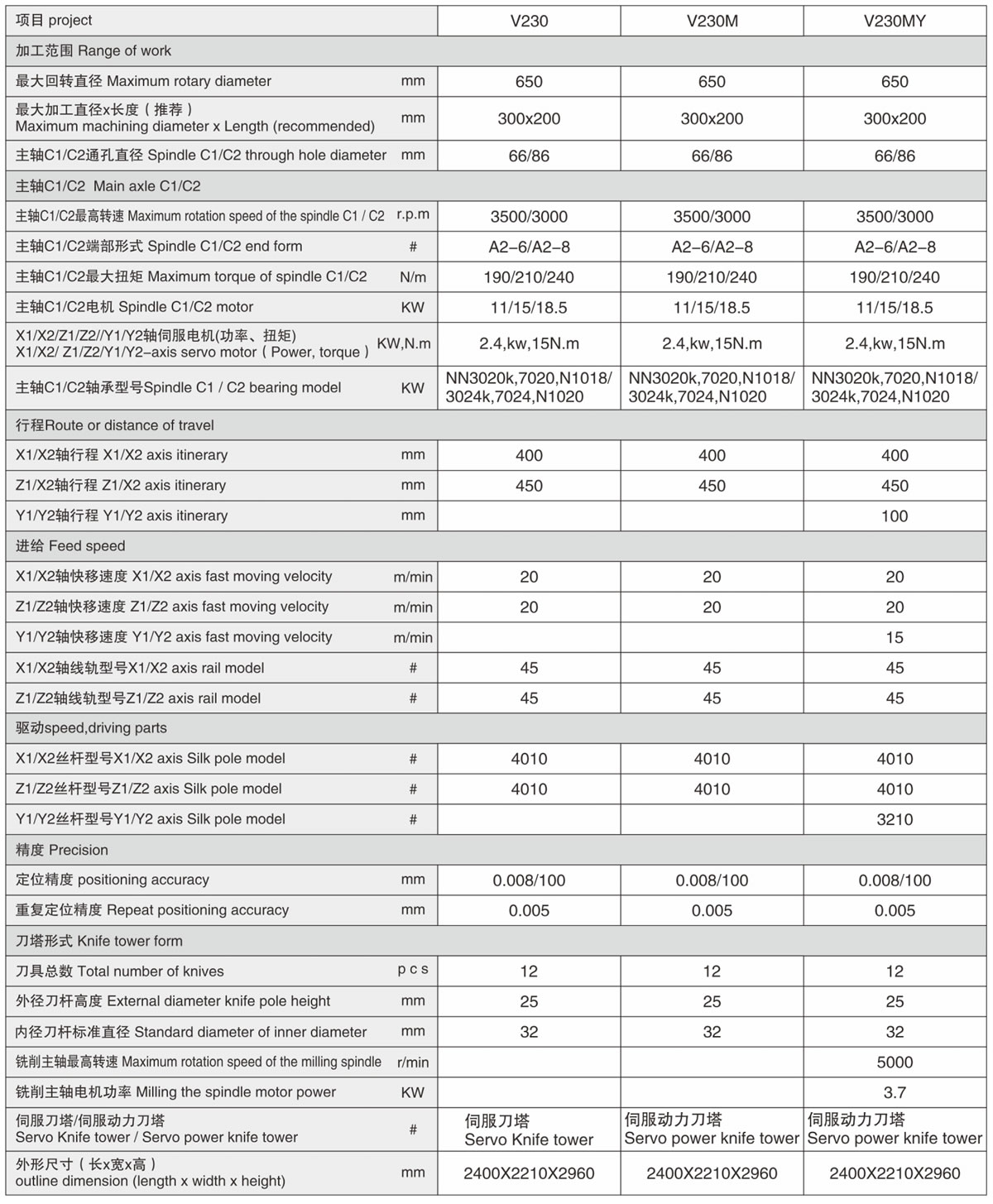

This type of machine tool can be equipped with servo knives, servo powered knives, and Y-axis servo powered turrets. Through this method, it is possible to achieve the functions of machine tool turning and turning compound processing.

Contacts Us

Chat with us

Do you have any questions or suggestions? Please contact us. Our working hours are from 9am to 6pm