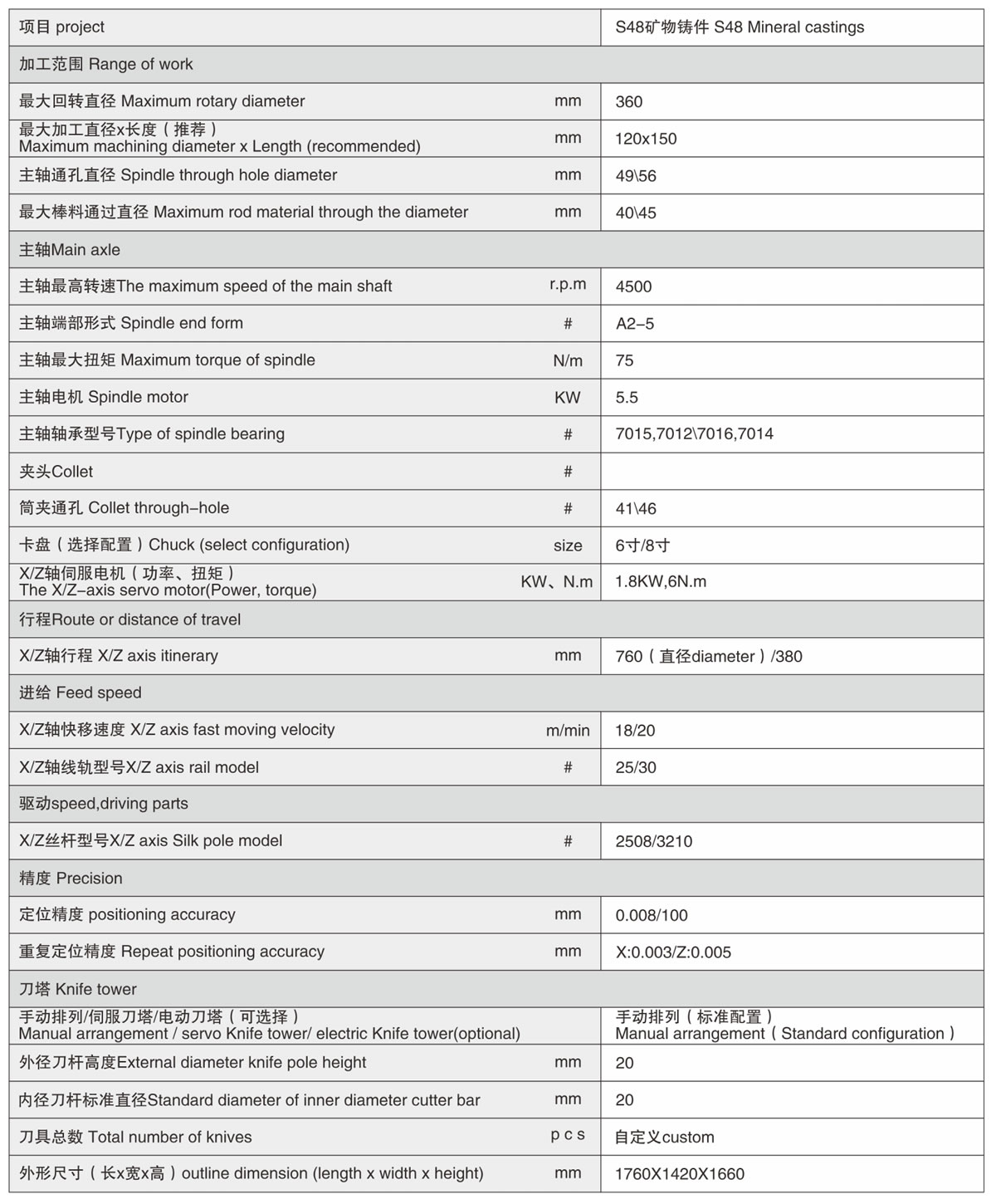

The S48 mineral casting CNC lathe is a patented product of our company, with patent number ZL20182077626.7. It is a type of integral asynchronous bed head, ZL201821895511.4.

CNC lathe with direct drive spindle.

This CNC lathe comes standard with a five axis (XZCAB) semi closed loop control CNC lathe system.

The standard configuration is a three-axis control cxz, and the host adopts a horizontal layout. The X drag plate is an integrated drag plate.

The X-axis and Z-axis are in the same plane.

The spindle (C-axis) is an AC asynchronous servo spindle directly driven by a driveless mechanism, which achieves position control and speed control. The spindle can rotate, feed, index, and stop accurately, and can be extended to two axes in the later stage on the drag plate.

Spindle clamping is achieved by using a hydraulic rotary cylinder to drive a three jaw chuck or an elastic chuck to clamp the workpiece.

X. Z is driven by ball screw, rolling linear guide rail, and the guide rail protection adopts full protection, using absolute value AC servo motor. Machine tools have good dynamic characteristics, high accuracy, and strong rigidity.

Mineral castings themselves have significant characteristics, such as excellent shock absorption and high integration with other components of the bed; And extremely high precision, etc.

Currently and in the future, energy prices have skyrocketed and will continue to rise.

This will highlight the superiority of low energy consumption in the production of mineral casting bed bodies.

The high precision of mineral casting bed can be achieved during casting without the need for external traditional machining, which will greatly reduce transportation costs and shorten supply cycles.

Contacts Us

Chat with us

Do you have any questions or suggestions? Please contact us. Our working hours are from 9am to 6pm